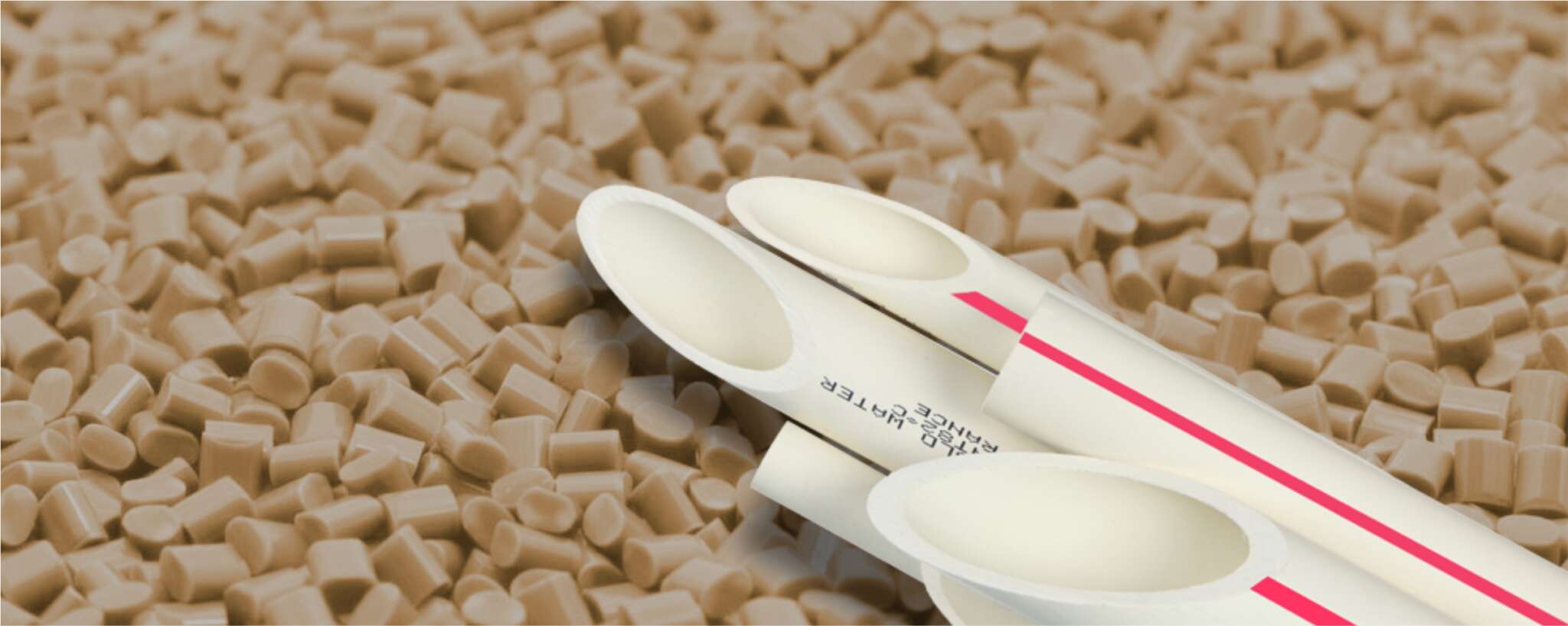

CPVC, an abbreviation for Chlorinated Polyvinyl Chloride, represents thermoplastic materials resulting from the polymerization of vinyl chloride along with the incorporation of chlorine gas. This particular production process yields a material that exhibits heightened resistance to heat, chemicals, and mechanical stress when compared to standard PVC compounds.

CPVC compounds find widespread utilization in various applications, encompassing hot and cold water piping systems, industrial piping, fire suppression systems, and electrical conduits. They are also integral in the fabrication of fittings, valves, and other components for piping systems.

The advantages of CPVC compounds over alternative materials are as follows:

Elevated Temperature Endurance: CPVC compounds demonstrate the capability to withstand higher temperatures than conventional PVC compounds, rendering them suitable for deployment in high-temperature scenarios.

Enhanced Chemical Resilience: CPVC compounds exhibit superior resistance to chemicals when compared to standard PVC compounds, making them appropriate for use in corrosive settings.

Augmented Mechanical Robustness: CPVC compounds boast enhanced mechanical strength in comparison to standard PVC compounds, making them well-suited for applications that entail high-pressure or mechanical stress.

Improved Fire Resistance: CPVC compounds feature enhanced fire resistance attributes relative to regular PVC compounds, making them suitable for use in fire suppression systems.

On the whole, CPVC compounds represent a versatile material endowed with exceptional properties and characteristics, facilitating their application in a broad spectrum of scenarios.